Fruit dyes are already on the market

Natural dyes are always used in textiles, and the growing awareness of sustainability and the need for nontoxic dyes has led to a variety of do-it-yourself "green" dyes that are easy to find online. A group of Chinese researchers specialise in fruit dyes and try to make them bigger.

An emerging trend

Only Patagonia's "Clean Color" line of fashion clothing, which includes t-shirts, sweatshirts, shorts and jackets that use natural dyes, is dyed indigo blue with indigo plants, carmine worms with magenta, pomegranate yellow and brown, and green with unpoetic Chinese silkworm feces. Natural dyes, of course, are less durable than their chemical counterparts, but are cleaner and capable of changing over time and washing times, giving the fabric a rather unique "live" look and opening up new design possibilities. In addition to this example, there are a number of testing and research projects going on around the world, but here is one of the most advanced. What are its outstanding features? It only uses fruit for coloring!

Drinkable dye

A small Chinese company has successfully developed a "fruit dye". They spent eight years researching and experimenting with a variety of fruits, finally achieving the desired results, and began offering products to the market. The new technology redefines the boundaries of eco-textiles and opens up a variety of applications. Now you can use pure juice to produce colored fabrics without adding any chemicals. "In the case that no chemical auxiliaries and chemical pigments are added when dyeing and finishing, the test indexes of finished fruit dyeing cloth can still reach the standards of gb18401-2010 and gb31701-2015. Fruit dye reaches GB 19297-2003 "fruit and vegetable juice drink health standard"! Said the inventor. Fruit-dyed textiles are especially suitable for baby clothing, children's clothing, underwear, casual clothing, as well as bedding, eco-friendly and caring for the skin.

To save water

We all know that chemical dyeing still requires a lot of water, and in many cases still produces a lot of waste, despite the great efforts already made by the plant. "Dyeing one kilogram of textiles: about 50 to 150 liters of water is needed for conventional chemical dyeing, which means tens of millions of tons of water are consumed every year... It only takes about 1.5 liters of water to dye the fruit, saving tens of millions of tons of clean water each year and creating greater benefits for our water resources on the planet. As producers know, "textiles in general often use traditional chemical dyes to produce tens of millions of tons of waste water each year for blending chemicals. Dyeing wastewater contains a large number of harmful substances: alkali sulfide, aniline, copper sulfate, formaldehyde, cyanide, etc. If not treated well, it will seriously damage the earth's ecological environment and cause harm to human health. And fruit dyeing, which is natural dyeing, will not produce any chemical waste water.

Fiber and color

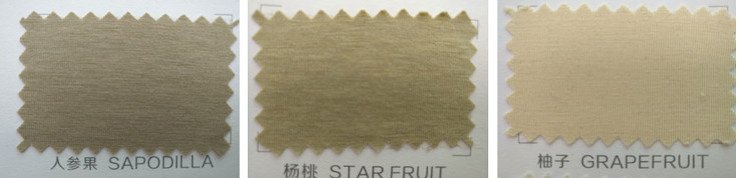

Of course, fruit dyeing can only be used for natural fiber, cotton, wool, silk, hemp, bamboo fiber, corn fiber, as well as natural fiber, mordale and other cellulose fiber. More than 10 colors have been successfully developed so far, but "we still need to constantly add more product test results to achieve a-level new colors," the company representative said. The current color comes from: apple, banana, dragon fruit, orange, carambola, mangosteen, mangosteen, longan, lemon, grapefruit, wild fruit, coconut and heart fruit, but a variety of lighter or darker tones should be appreciated for the combination of multiple fruits.

Product identification

Over the past year, the identification scheme of fruit dyeing products is taking shape, and the national industry standard of fruit dyeing products will be formed as soon as possible.

Fruit dye industry supply chain including scientific research, production, sales and service, the whole industry chain including GuoMiao cultivation, agricultural cultivation, fiber, spinning, weaving, clothing, brand to third party service, the synergy has established the "fruit dye industry alliance", "fruit ecological green innovation development, the theme of the height, can not only enhance the brand products, improve product added value is fruit dye industry alliance entrepreneurs have a strong social responsibility. "

How does fruit dye work?

Once the fruit is ripe, it is picked and stored, then extracted and prepared according to the desired hue. The fabric is pretreated before dyeing, and then the fruit is finished. The final color results depend on the combination of different fruits, the type of fabric used, and the state of natural light. Fruit dyeing adopts an innovative dyeing and finishing process, which is carried out at room temperature. There is no need to consume steam during the dyeing process, no chemical auxiliaries and chemical dyes, and no sewage discharge during the entire dyeing process.

What are the main problems for underwear companies in using this new process?

The main problem that the underwear enterprise faces when using the new technology of fruit dyeing is the control of the temperature in the production process. The characteristics of fruit dyeing products are purely natural, healthy and comfortable. After dyeing, the cloth surface will form a layer of natural active pectin, which produces a unique soft gloss, which increases drenching, breath-taking and skin-friendly. The pure natural fruit pigment is completely consistent with the light source of natural light. To avoid damaging the benefits of fruit dyeing, the ironing temperature should not be too high (similar to traditional silk products).

Is there any big factory producing fruit dye (fabric)?

No, there are no other factories producing fruit dye (fabrics). Only the fruit dyeing production patent and registered trademark manufacturers have production rights.

How long can the color stain?

The color fastness to water can reach level 4 according to the international standard accepted by quality, which means the color can last more than 2 years.

Move to a cleaner future

At present, we can't solve all the problems of chemical dyeing pollution. However, by vigorously promoting fruit dyeing, starting with underwear and home textile, we can solve the problem of textile pollution in some categories, which has made an inestimable contribution to the ecological industry.

If more enterprises are involved in ecological construction and more consumers can only use green, environment-friendly and healthy products, then the social value of the fruit dyeing project that has been developed for eight consecutive years can be truly reflected.

It is the trend of The Times to support green and clean production, promote the green transformation of traditional manufacturing industry, and help establish an industrial system of green and low-carbon development cycle.

Through natural environmental protection, only picking fruit without cutting down trees, planting fruit trees on a large scale in rural areas can greatly reduce the pollution generated during the dyeing and processing of traditional textile and clothing products. This will benefit farmers who grow the raw materials needed for fruit dyeing, creating a virtuous ecological cycle from agriculture to industry to consumption.

Contact: Lily Wang

Phone: +86-15067102905

Tel: +86-15067102905

Email: lily@lihaisilk.com

Add: KongFen Building1-603, 299# Miaohouwang Road,Xixing Street,Binjiang District,Hangzhou,China.